Whether you’re packaging food, e-commerce items, or retail products, a side sealer is a key player in making your line run smoothly. These machines use shrink film to wrap products tightly, protecting them while giving a clean, professional look.

But here’s the tricky part: should you go for a continuous side sealer or an intermittent motion side sealer? At first glance, they look similar, they both wrap products in shrink film but the way they work and the results they give are very different.

No worries! You’re in the right place. Let’s break it down in a simple, easy-to-understand way so you can pick the shrink equipment that works best for your business.

A side sealer is a fully automatic shrink sealer that continuously wraps products in shrink film while sealing along the side of the package and again with a cross seal bar in the front of a package. Unlike an L-bar sealer that seals one product at a time across both ends, a side sealer runs products of different lengths without stopping for adjustments. Perfect for keeping operations fast and efficient.

From food packaging to retail and e-commerce, side sealers are everywhere because they make packaging faster, easier, and more reliable.

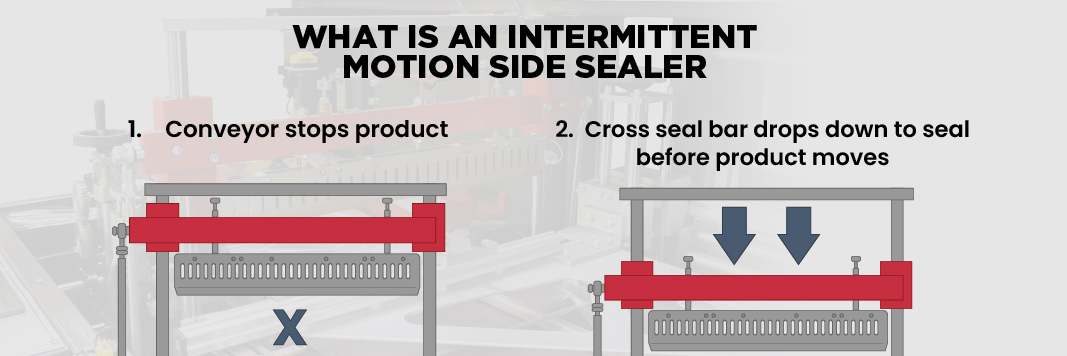

An intermittent motion side sealer is the “stop-and-seal” option. Each product pauses briefly while the machine seals the shrink film, creating a neat, tight package.

These machines are flexible and budget-friendly, perfect for smaller runs or products of different sizes. If your line changes often or you handle seasonal items, an intermittent side sealer is a solid choice.

Why intermittent side sealers are popular:

The trade-off? Because each product stops for sealing, intermittent side sealers are slower than continuous models. But for many businesses, their flexibility and affordability make them a smart choice.

A continuous side sealer takes a completely different approach. It is all about speed and efficiency. Instead of stopping each product, the sealing bar moves along with the item, sealing the shrink film as it travels down the line.

These machines shine in high-volume operations where every second counts. They keep products moving, reduce bottlenecks, and deliver clean, professional seals at scale.

Key advantages include:

The main consideration? They usually have a higher upfront cost and work best with products of similar sizes. But for busy lines, they can save a ton of time and keep your workflow efficient.

Now that we’ve explored both types, let’s break down the main differences between continuous side sealers and intermittent motion side sealers. Understanding these differences will help you pick the right shrink equipment for your production line.

| Feature | Intermittent Side Sealer | Continuous Side Sealer |

| Operation | Stops each product to seal | Moves alongside product, sealing as it travels |

| Speed | Slower, ideal for small runs | Fast, perfect for high-volume runs |

| Flexibility | Handles mixed product sizes easily | Best for uniform sizes |

| Cost | Lower upfront cost | Higher upfront cost |

| Best For | Short runs, seasonal products | Large-scale production |

Key Takeaways

In short, there’s no one-size-fits-all solution. Understanding the differences ensures you pick the side sealer that keeps your products moving efficiently while maintaining professional-quality packaging.

|

|

| (PP-5545TBH Intermittent) | (PP-5545TBJ Continuous) |

Before picking a side sealer, consider your production needs:

Here’s a quick look at how different industries typically choose their shrink equipment:

By answering these questions and looking at industry examples, you can quickly identify which side sealer will keep your shrink film packaging efficient and professional.

Picking the right side sealer doesn’t have to be overwhelming. It all comes down to your production needs, product variety, and speed requirements.

Intermittent motion side sealers are flexible and cost-effective, perfect for smaller runs or products of varying sizes. Continuous side sealers are built for speed and consistency, making them ideal for high-volume production.

The best approach is to match your side sealer to your workflow. Consider your daily output, product sizes, budget, and how important speed is to your operation. Looking at how similar industries use these machines can also provide helpful guidance.

With the right shrink equipment, your shrink film packaging will run smoothly, look professional, and keep your production line efficient, no matter your products or volume.