Ever unwrap a product only to find it being wrinkled, bubbly, or just… messy? Not only does it look unprofessional, it can also slow down your line, waste materials, and cost your business money. The good news? Choosing the right shrink film, and understanding how air escapes during the process, can transform your packaging efficiency.

Let’s explore perforated vs. non-perforated shrink film and determine which is best for your line.

Shrink Film Basics

Shrink film is a flexible plastic wrap that hugs your products tight when heat is applied, giving them a secure, polished look. From food and beverages to electronics, it keeps items protected and neatly bundled. But trapped air can cause bubbles, wrinkles, or tears, so controlling how air escapes is key.

While shrink film comes in materials like PVC, polyolefin, and polyethylene, one of the biggest factors for a perfect wrap is whether it’s perforated or non-perforated.

What is Perforated Shrink Film?

Perforated shrink film comes with tiny, evenly spaced holes that let hot air escape as the film shrinks, making a huge difference in wrap quality. The benefits? Fewer bubbles and wrinkles, tighter and cleaner wraps, and a polished, professional look every time. It’s perfect for high-speed lines or oddly shaped products.

Common uses include food multipacks, retail-ready printed packaging, and bundling unevenly shaped consumer goods. By controlling how air escapes, perforated film keeps your wraps flawless and your production line running smoothly.

Benefits of perforated film:

Perforated film ensures air escapes in a controlled way, keeping your wraps professional and your line running smoothly.

What is Non-Perforated Shrink Film?

Non-perforated shrink film is solid with no pre-punched holes, giving your products maximum protection. While it doesn’t naturally release air, it’s perfect for shielding items from moisture, dust, and contamination. It’s the go-to choice for tamper-evident or retail-ready packaging. Common uses include electronics, cleanroom or sterile products, and high-value items that need a strong, secure seal.

Benefits of non-perforated film:

Non-perforated film is ideal when protection comes first, though managing trapped air is key to keeping wraps smooth and professional.

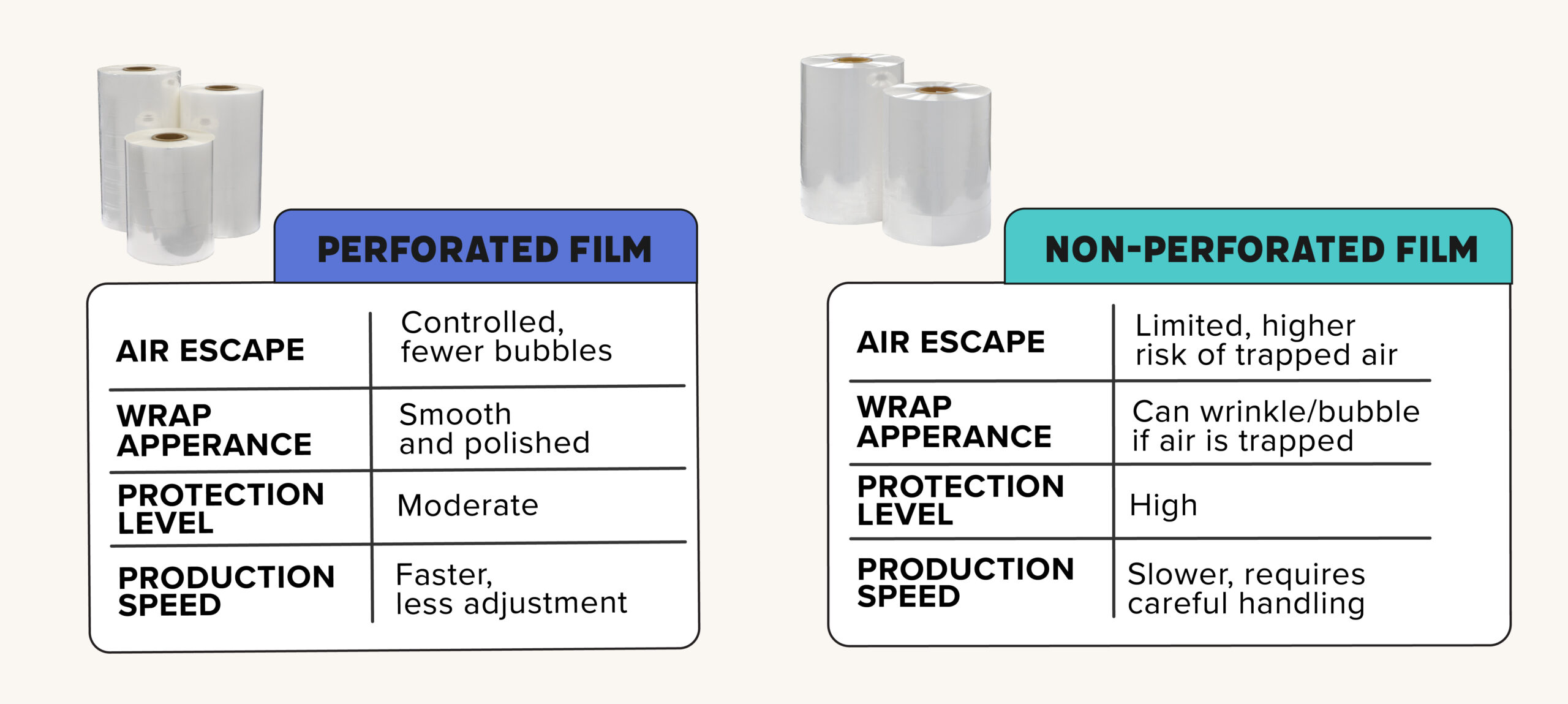

Perforated vs. Non-Perforated: How They Compare

Here’s a quick comparison to highlight the differences:

| Feature | Perforated Film | Non-Perforated Film |

| Air Escape | Controlled, fewer bubbles | Limited, higher risk of trapped air |

| Wrap Appearance | Smooth and polished | Can wrinkle/bubble if air is trapped |

| Protection Level | Moderate | High |

| Production Speed | Faster, less adjustment | Slower, requires careful handling |

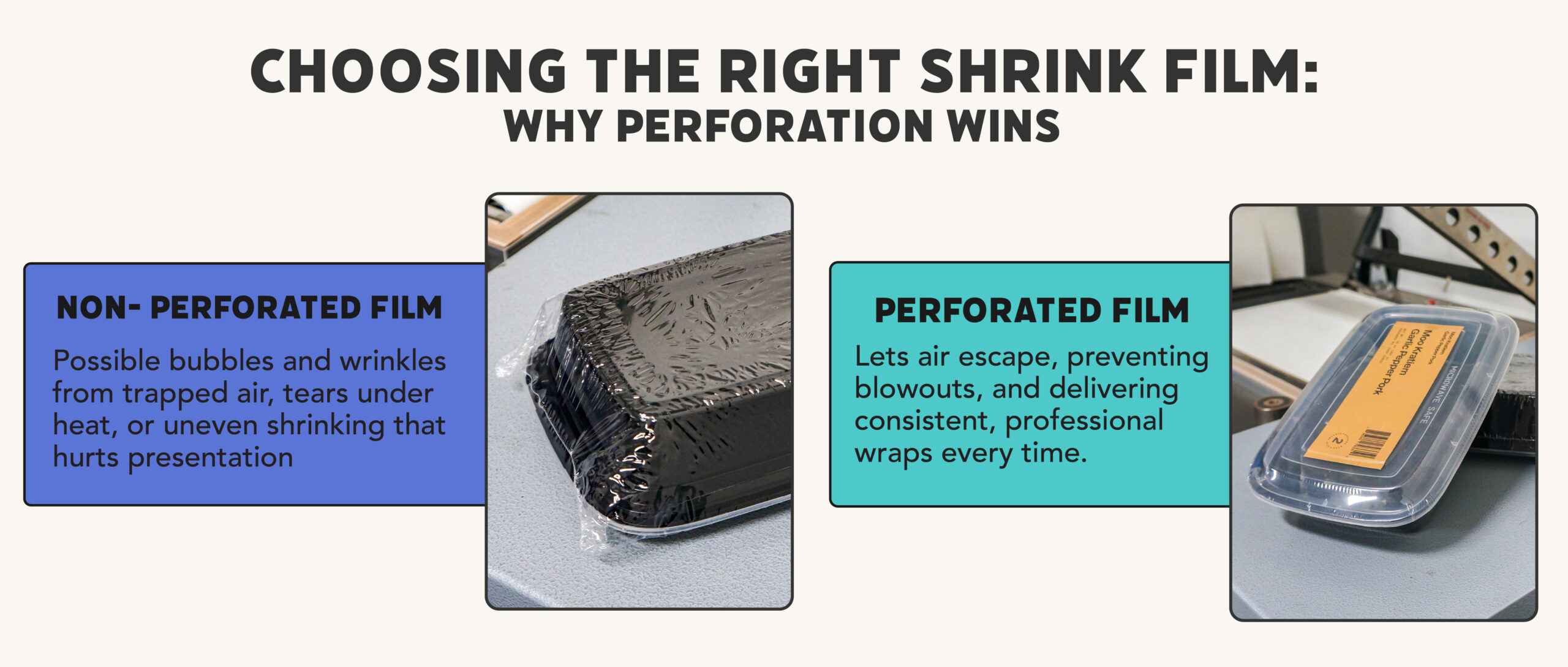

Choosing the Right Shrink Film: Why Perforation Wins

Selecting the right shrink film isn’t just about material, it’s about performance. While non-perforated film has its place for fragile items or products needing extra dust protection, perforated film is the clear choice for most applications. From retail packaging that demands a flawless finish to high-speed production lines that rely on efficiency, perforation makes the difference.

Without it, you risk common issues: bubbles and wrinkles from trapped air, tears under heat, or uneven shrinking that hurts presentation. Perforated film, and machines with built-in perforation wheels—solves these problems by letting air escape, preventing blowouts, and delivering consistent, professional wraps every time.

That’s where BPX machines shine. Their built-in perforation wheel creates precise micro-holes on the fly, giving you the best of both worlds: the flexibility to run non-perforated film when needed, but always with the smooth, reliable results perforation provides. No wasted time on roll changes, no second-guessing—just flawless packaging at full speed.

Wrap-Up

When it comes to shrink film, perforated wraps give you smooth, bubble-free results and help speed up your production line, while non-perforated film delivers maximum protection for delicate or high-value products. Add BPX machines with built-in perforation wheels, and you get ultimate flexibility, efficiency, and consistently flawless results.

Still wondering which film is best for your line? Connect with our packaging experts today and keep your wraps tight, your products safe, and your production running like clockwork.

In packaging, sometimes the tiniest holes make the biggest difference!