As we’re stepping into the eighth month of 2019, the new year is just around the corner! With only five whole months left in this year, you’re probably wondering how to achieve your company’s goals, you may in fact be close to your goals. We are here to help you to bring your business to the next level and to end 2019 with a bang!

In this article we’re going to go over exactly how, by implementing certain tools, and by replacing out some specific things which could be slowing down your success, you can take your business to the next level – without a huge investment of capital or time in the implementation.

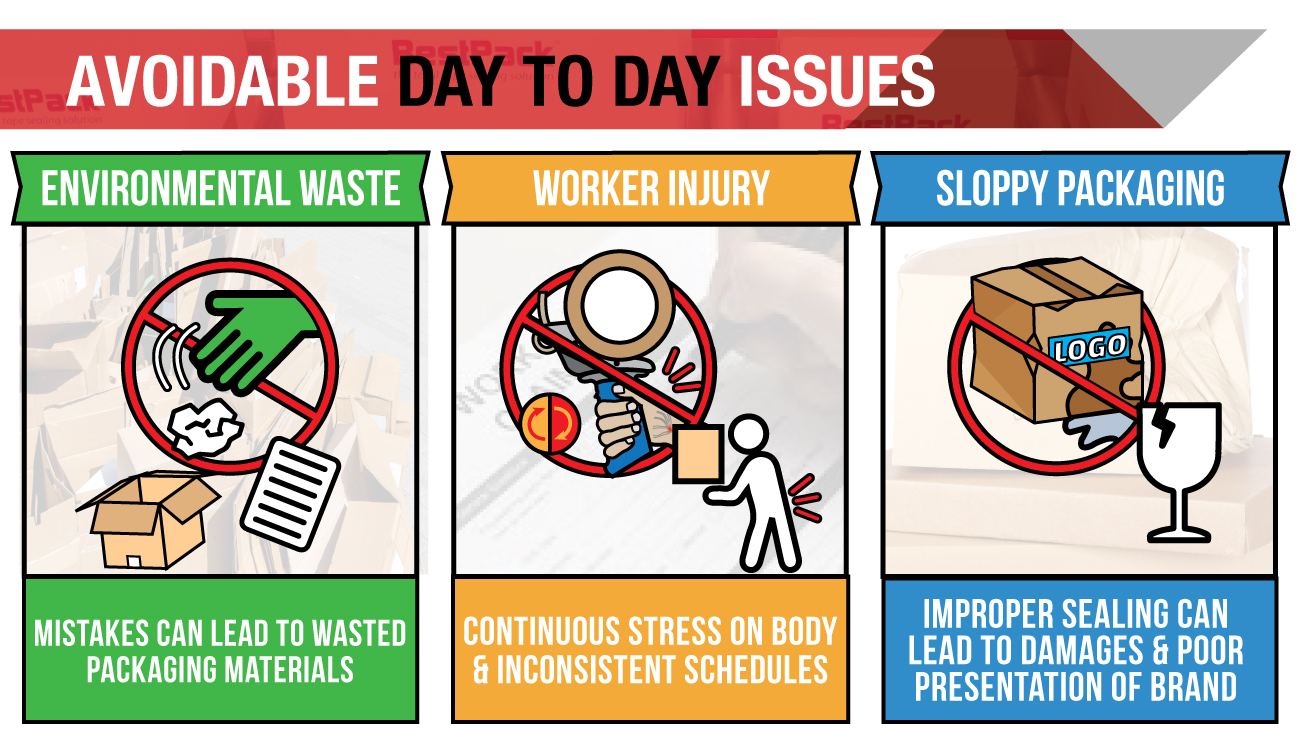

Now, let’s take a brief look at some things which may be inhibiting your ability to meet quotas and within budget:

By having a machine that erects your cartons perfectly every single time, a machine that always seals the cartons to exact or adjusting specifications and a finished product that looks clean, professional and uniform every single time can have significant effects on the consumers end when receiving your finished product. A professional looking seal and package can go a long way to bringing your brand to the next level in the eyes of the public.

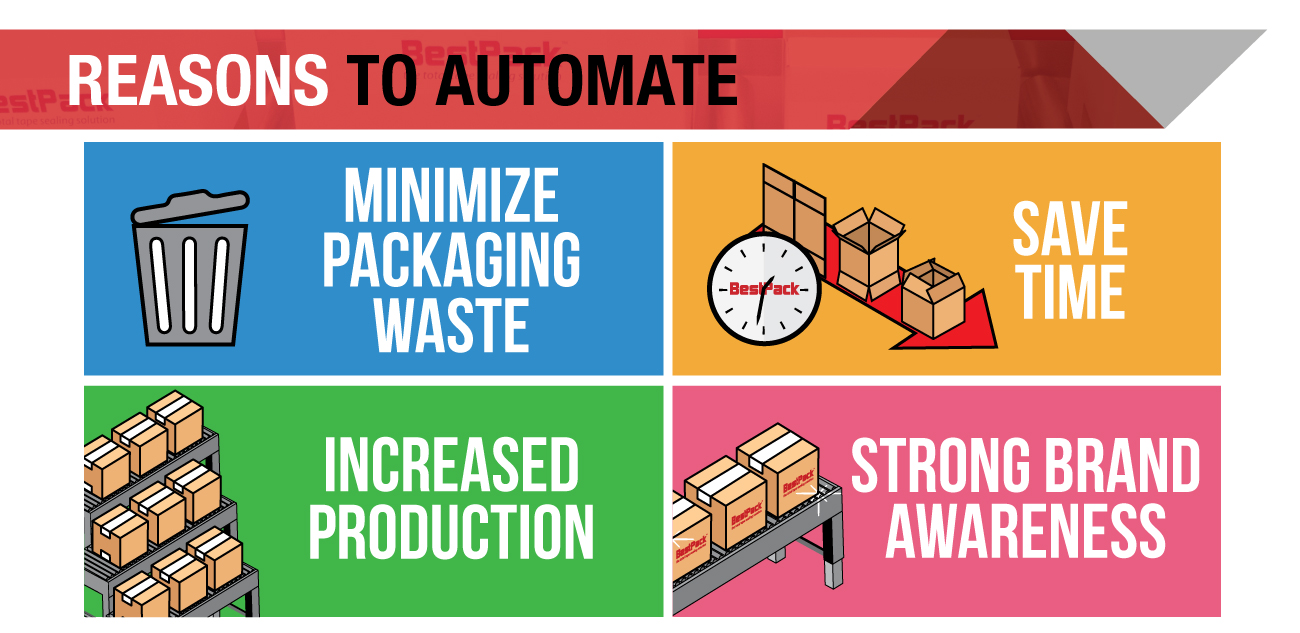

Why You Should Automate Your Packaging Line With the implementation of a top-quality and streamlined packaging line, customized and automated to fit your business needs, this can have a massive impact on production. You can easily and accurately quantify how many boxes you can erect, fill, seal and have completely ready for shipping in a given minute, hour, day or week. Thus helping you to predict how many hours of operation are needed to meet certain quotas. Factor in the lack of waste, the fact that the machines don’t need to take lunch breaks and the finished product is professional and excellent, this can have quite an impact on a business that has to box up and store or ship out large quantities of products.

With the implementation of a top-quality and streamlined packaging line, customized and automated to fit your business needs, this can have a massive impact on production. You can easily and accurately quantify how many boxes you can erect, fill, seal and have completely ready for shipping in a given minute, hour, day or week. Thus helping you to predict how many hours of operation are needed to meet certain quotas. Factor in the lack of waste, the fact that the machines don’t need to take lunch breaks and the finished product is professional and excellent, this can have quite an impact on a business that has to box up and store or ship out large quantities of products.

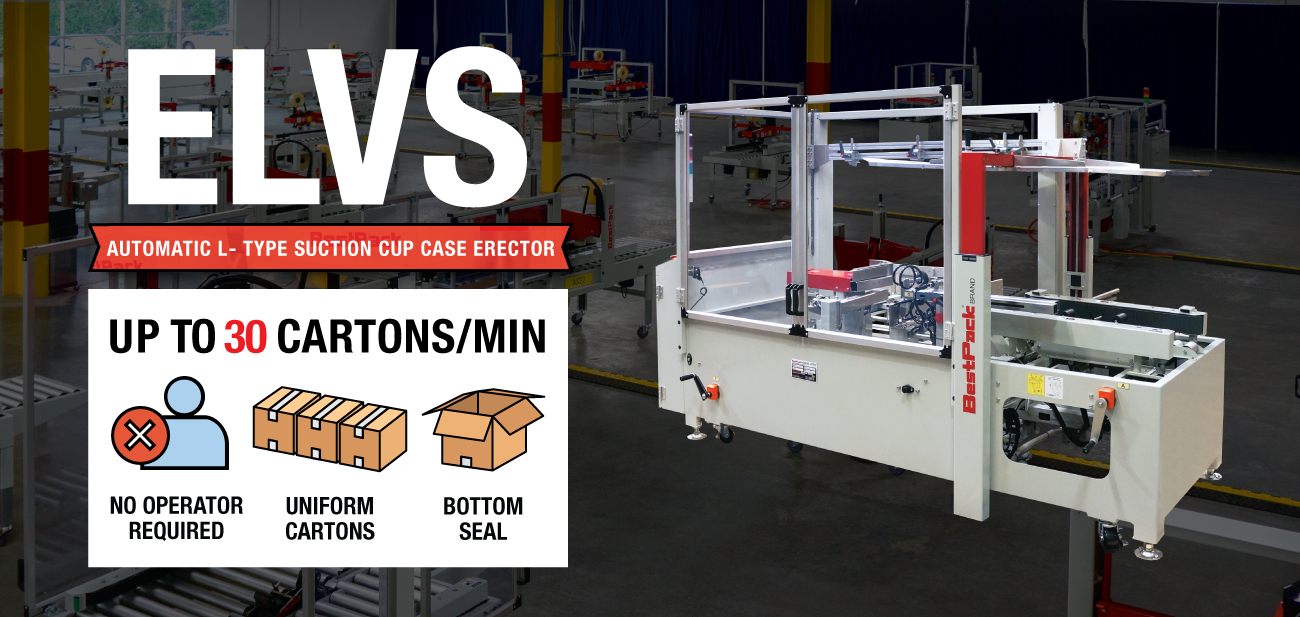

Now, what are some actual solutions to the problems you might face?

The model ELVS is an innovative, high performance carton erector/sealer. This erector is built for heavy usage with quick and simple carton size changeover. Able to erect up to 15 cartons per minute, this will easily double if not triple your production line, while maintaining a small footprint in your production line. If you are looking for a simple yet heavy-duty built carton erector, this is a must-have system.

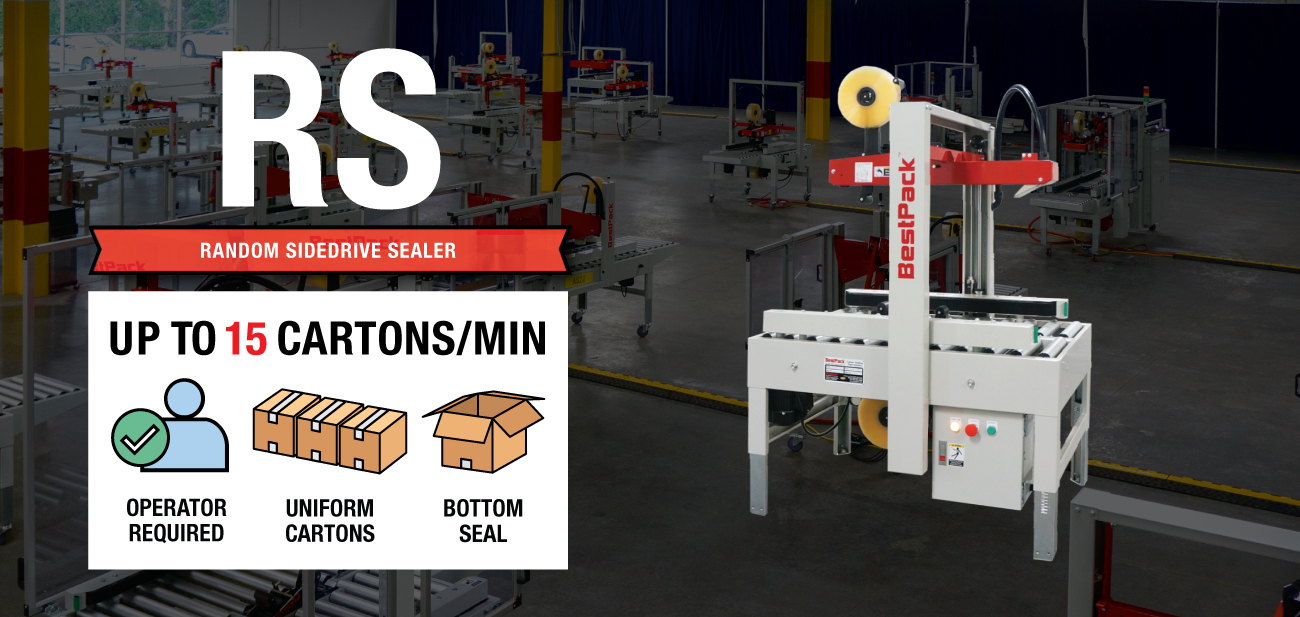

Meet the RS – Random Side drive.

The BestPack RS is a semi-automatic random tape carton sealer built for efficiency and rugged dependability. This operator free machine easily seals a wide range of random carton weights and sizes. Able to effectively seal very light to very heavy cartons, and is able to seal up to 15 cartons per minute. BestPack’s RS sealer is a workhorse and the most flexible unit in our random sealer product line. This machine can be customized to cater to your business’s specific needs and applications, such as pre-position for uniform carton sizes, safety gates, low tape/no tape sensors, elongated masts and more!

BestPack’s Custom Packaging Tape:

If you’re not branding yourself, you’re missing out on opportunities to get more customers! BestPack has you covered with our Custom Printed Tape (available in surface & lock print). Give your packages a professional advertising appeal that distinguishes your package from the rest. Never miss out on another lost opportunity again. Our custom packaging tape is an inexpensive way to get your brand out there!

Improving Environmental Impact:

With an excess of waste in the world it is our responsibility to make sure that we reduce our carbon footprint whenever we can. For you, it could start with your packaging materials. BestPack has developed, a specially formulated tape that works well with 100% recycled corrugated cartons – BG Tape. Manufactured in an environmental certified facility, it has the high tack properties that hot-melt users like and the protective properties to withstand extreme hot and/or cold temperatures. On top of that, using a BestPack carton sealer can also reduce your carbon footprint due to their long lasting durable materials.

The powerful combination of an automated Carton Erector, Carton Sealer and BestPack Tape will make your business unstoppable and creates room for expansion. Like we mentioned above, by freeing up your packaging line, you can put your employees on other tasks which can expand your business even further.

Bestpack has developed over 120 models of carton sealers sold in 48 different countries worldwide, as well as custom lines of packaging tapes developed to address specific applications. Proven and effective, BestPack has built a reputation founded on quality, innovation, & customization.

So let us do the hard work for you and your business for the rest of 2019 and into the future. Connect with us today.