When you think about packaging equipment, tape machines and carton sealers usually come to mind first. But here’s something many people don’t realize: poly bundlers play a huge role in keeping production lines moving smoothly. If you’ve ever grabbed a shrink-wrapped case of bottled water or canned goods at the store, chances are a bundler did the job.

So, let’s break down what makes them stand out, without all the jargon.

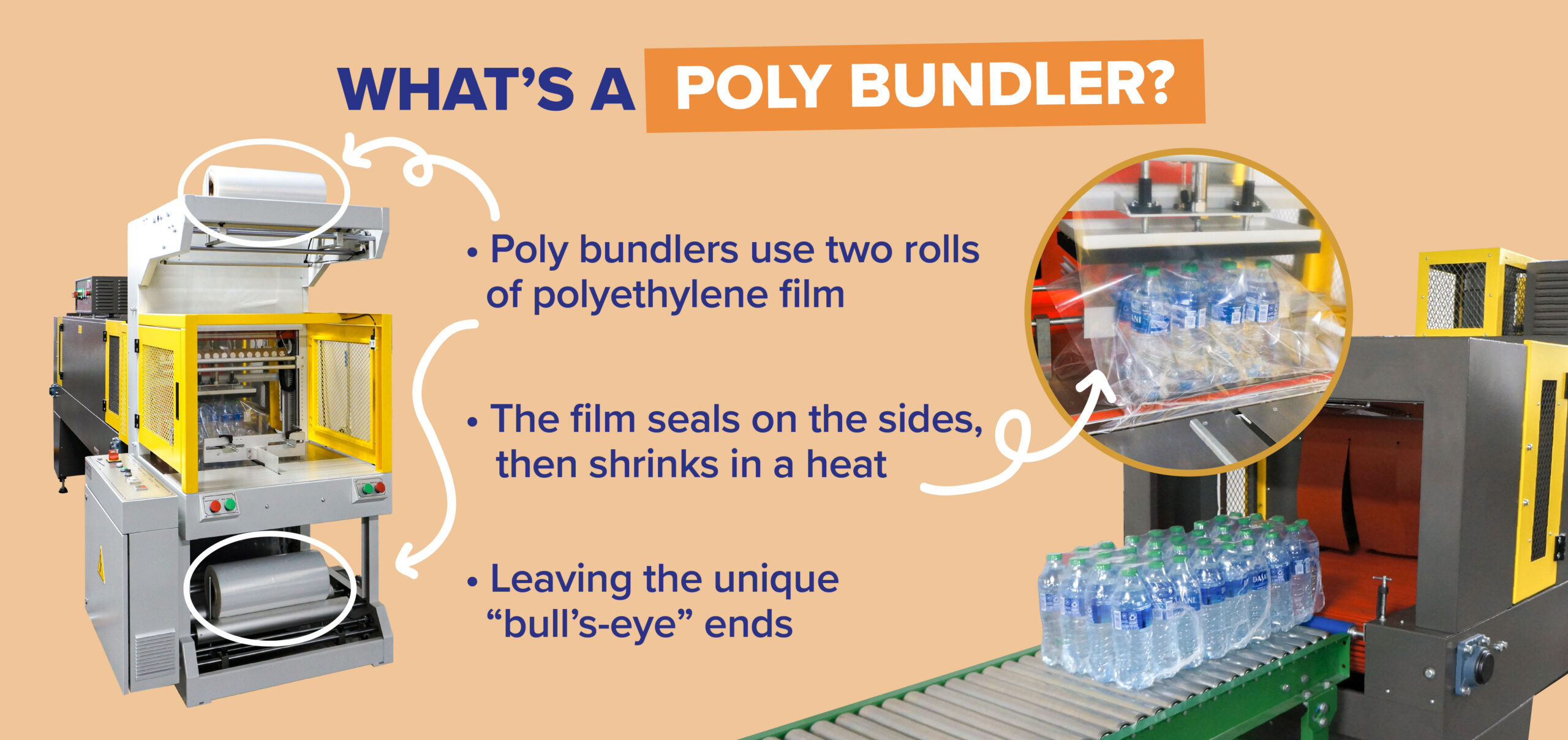

A poly bundler works by using two rolls of polyethylene shrink film—one positioned on the bottom and one on the top. As products move through the machine, the two layers of film meet and wrap around the items, creating a secure bundle that’s sealed on the sides. From there, the pack runs through a heat tunnel, which shrinks the film tightly around the product while leaving the signature “bull’s-eye” openings on the ends.

It’s a simple but highly efficient design that makes bundling multipacks faster and more cost-friendly. BestPack builds and sells the bundlers themselves, but not the film; we leave that to distributors so you can choose the right polyethylene film for your specific application.

One of the most unique features of a poly bundler is the bull’s-eye—that circular opening left on each end of a package after it’s been shrink-wrapped. At first glance, you might think of it as an unfinished seal, but it’s actually a deliberate design choice with real benefits.

Bull’s-eyes make packs easier to carry and handle, since customers can slip their hands right through the openings. They also allow for better air circulation, which helps reduce condensation on cold or frozen products. And because less film is needed to create these openings, the design cuts down on material use and packaging costs.

It’s a simple yet clever detail that sets poly bundlers apart from other machines, showing that sometimes the smallest design elements create the biggest advantages.

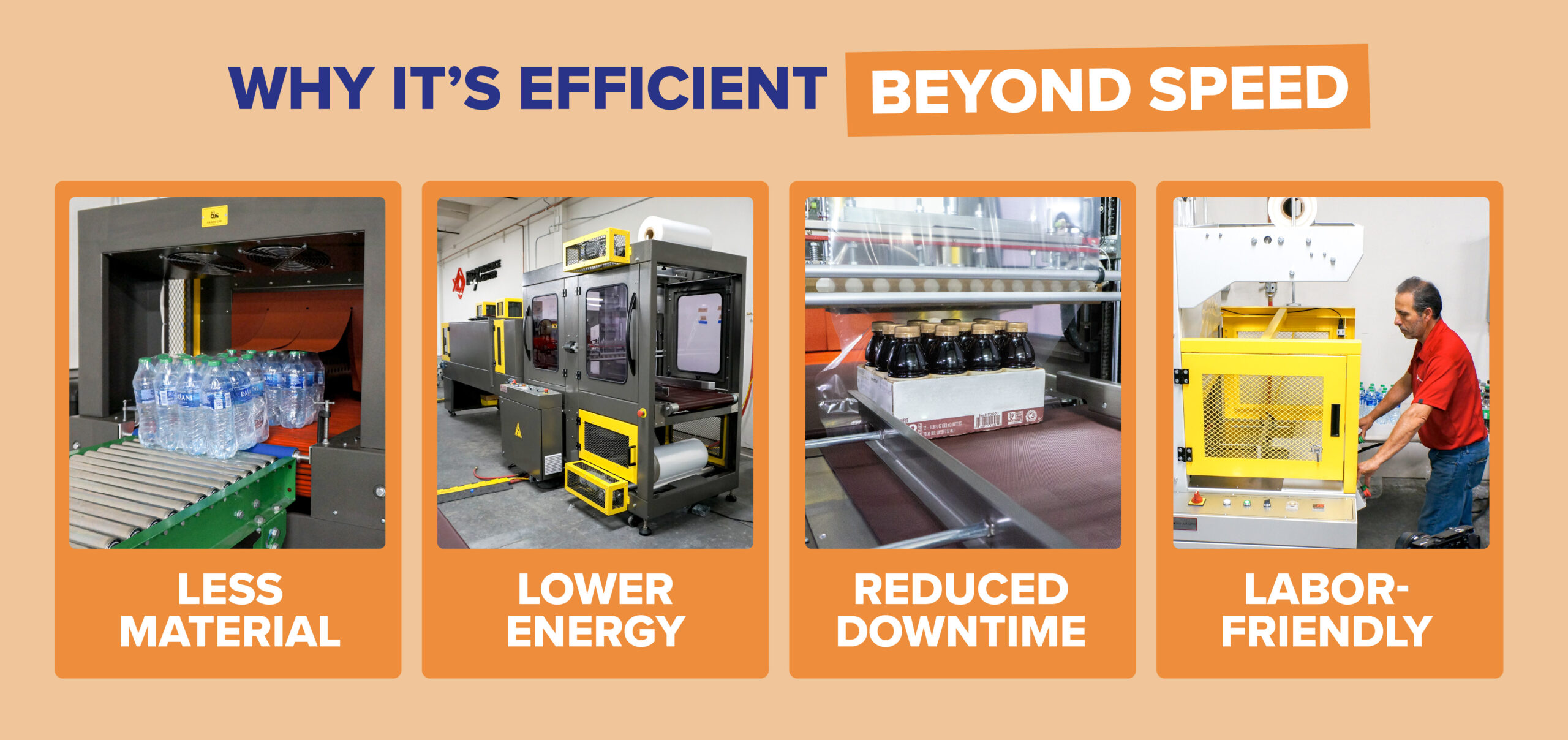

Yes, poly bundlers run fast—but the real benefit is how they save resources across the board.

Think of it as switching from tying your shoes to slipping them on, less effort, same secure fit.

Poly bundlers show up most often in industries that handle bulk or multipack goods:

Retailers love them because the packs are strong, stack neatly, and still give customers a clear view of what they’re buying. It’s packaging that balances protection, cost, and convenience all at once.

Cartons definitely have their place, they’re excellent for fragile products, detailed branding, or when extra protection is a must. But for bulk or multipack goods, poly bundlers often provide a simpler, lighter option.

By relying only on film, bundlers reduce the amount of material needed while still keeping products secure and shelf-ready. It’s less about choosing one over the other, and more about knowing which solution best fits the product.

Every production floor is different. The number of SKUs, your speed requirements, even the way your team handles packaging, it all plays a role in choosing the right automation. That’s why figuring out if a poly bundler is the right fit isn’t just about the machine, it’s about understanding your entire process.

This is where BestPack makes the difference. Our experts don’t just sell equipment—they work alongside you to evaluate your line, your goals, and your challenges to recommend the right automation solution. Sometimes that’s a poly bundler, sometimes it’s a different system—but the result is always a setup that helps your business run smarter.

If you’re wondering whether a poly bundler could streamline your packaging, connect with BestPack today. The right automation is out there, and our team can help you find it.