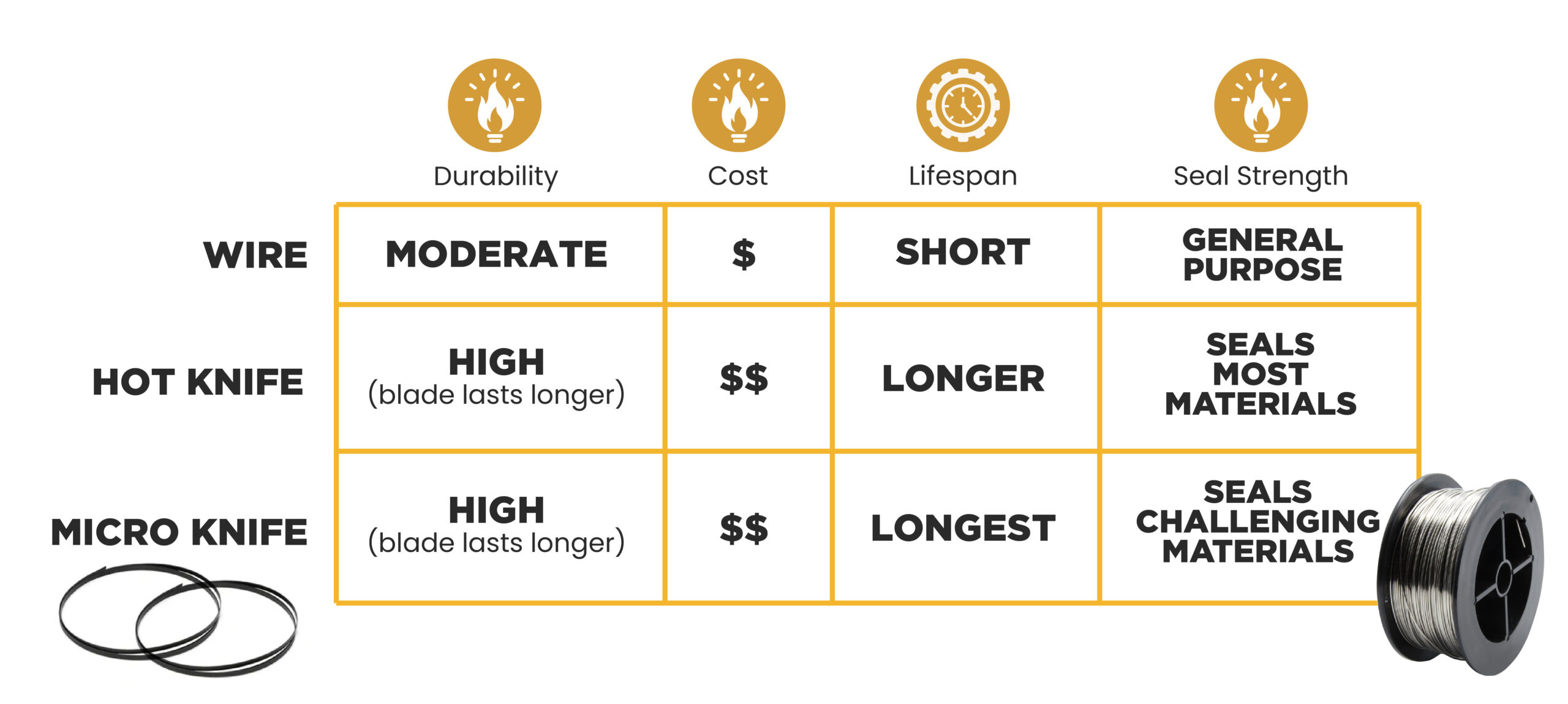

When it comes to shrink packaging, one size doesn’t fit all, especially when it comes to sealing. The type of seal you use can impact everything from how fast your line runs to how secure and professional your finished package looks. We offer three main types of seal bars: wire, hot knife, and micro knife. Each designed to handle different packaging needs, film types, and production goals. We’ll break down how each one works, where it performs best, and what to consider when deciding which is right for your operation.

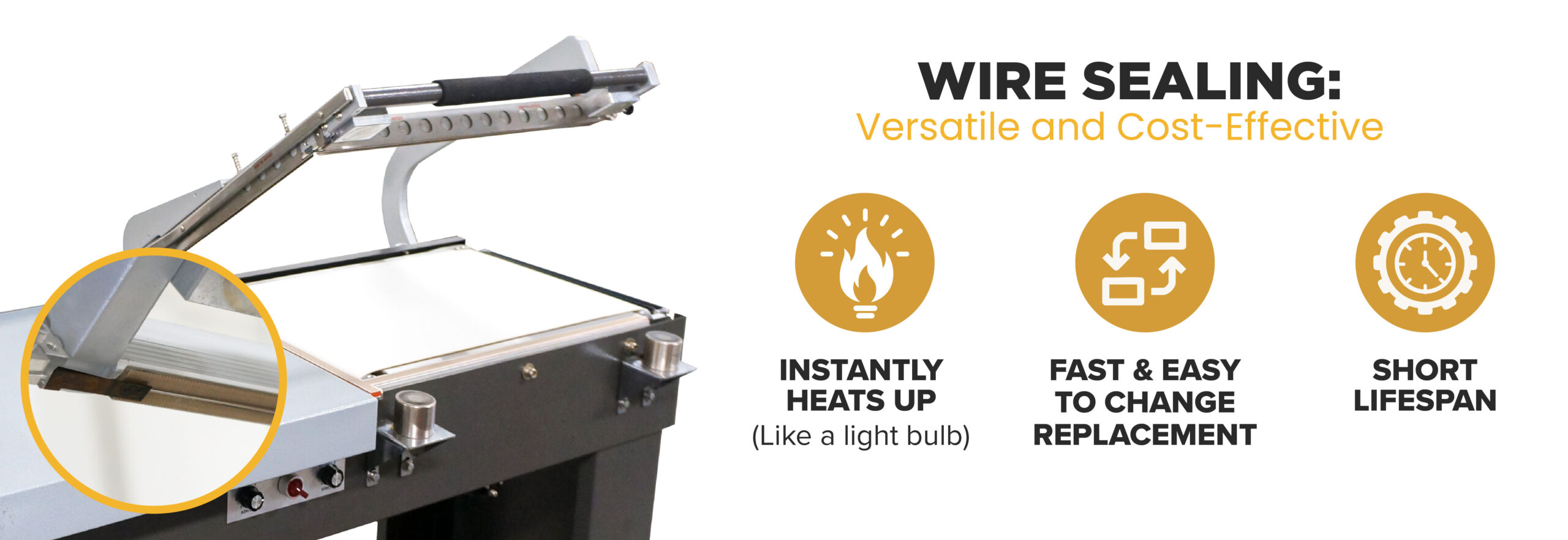

Wire Seal Bars: Versatile and Cost-Effective

Wire seal bars are one of the most common ways to seal shrink packaging. They use a thin wire that heats up quickly when electricity passes through it. This hot wire cuts and seals the film in one step. Wire seal bars are popular because they work well for many types of packaging and are fast.

Wire seal bars are also affordable and easy to set up. However, the wire can wear out faster since it’s exposed to heat and constant use, so it needs regular maintenance and replacement. Over time, residue can build up and affect performance. The seals made by wire bars are thinner, so they might not be strong enough for heavy-duty or tamper-proof packaging.

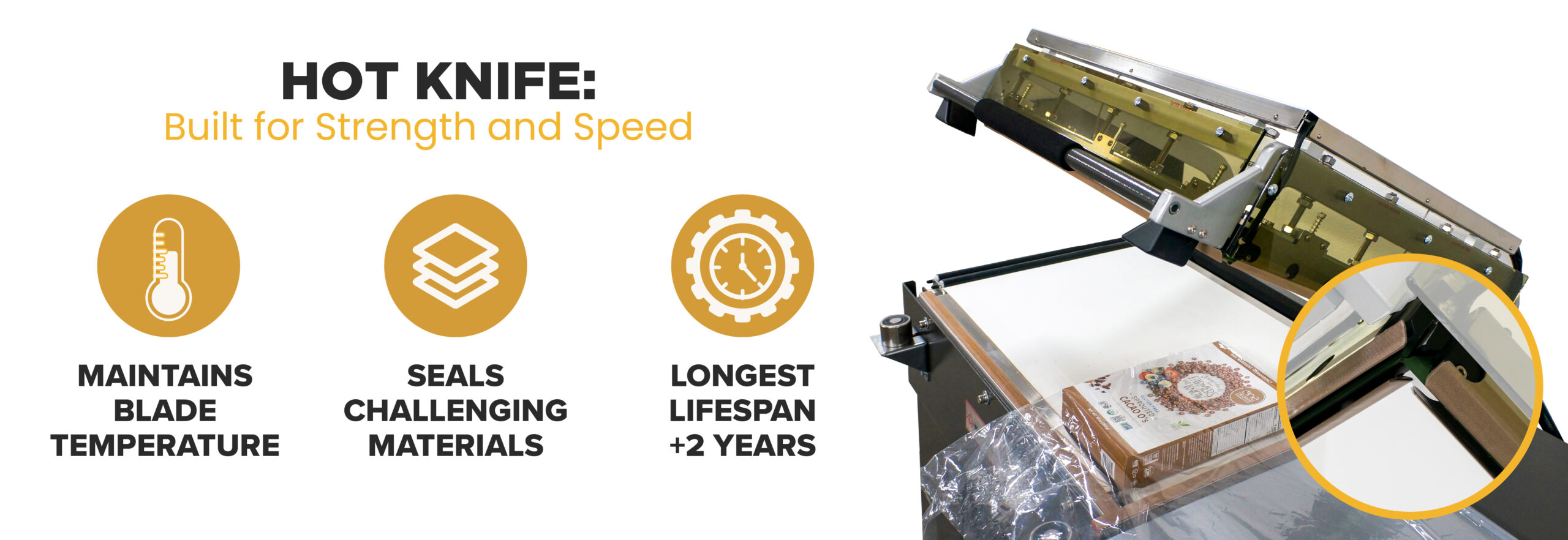

Hot Knife Seal Bars: Built for Strength and Speed

Hot knife seal bars work differently than wire bars. Instead of a thin wire, they use a solid, heated metal blade to melt through the shrink film. This blade is usually coated with Teflon to stop film from sticking and keeps a steady temperature, making a stronger and more durable seal. Because it holds heat well, the hot knife is great for heavy-duty packaging.

It’s perfect for fast production lines and can handle thicker shrink films that need more heat to seal properly. Although hot knife seal bars cost more upfront, they last longer and don’t need to be replaced as often, which can save money over time.

Micro Knife Seal Bars: Precision for Premium Presentation

Micro knife seal bars are made for precise, clean sealing and look great on finished packages. They use a thinner, specially designed blade that works at lower temperatures than hot knives. This means the seals are neat, with little damage or leftover residue on the film. Micro knives are perfect for products where the package needs to look attractive, like retail goods, cosmetics, and premium food items.

Because they use less heat, micro knives are also good for items that could be damaged by higher temperatures. Although they can cost more to maintain because of their precise design and heat requirements, they deliver the best results when appearance matters most.

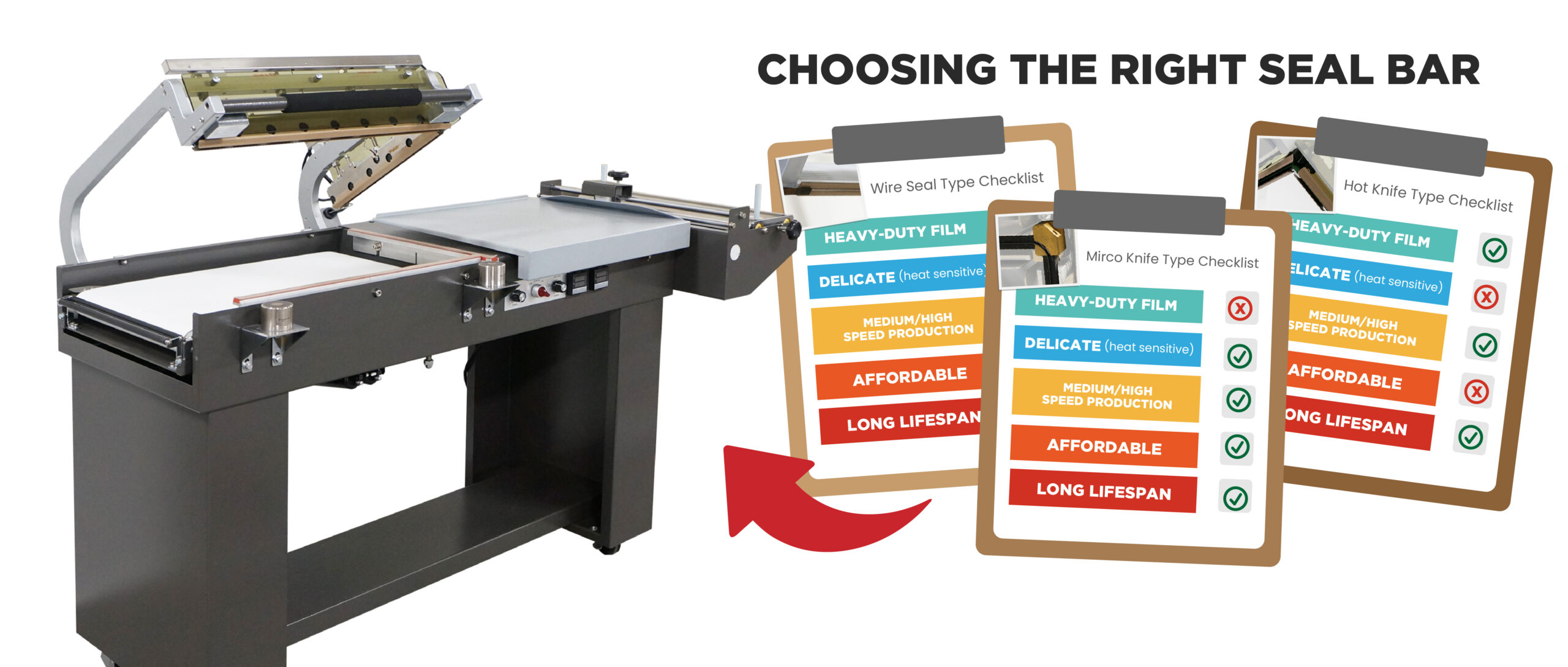

How to Choose the Right Seal Bar

When choosing the right seal bar for your packaging line, consider these key factors:

Considering these factors will help you pick the seal bar that best fits your packaging needs and keeps your production running smoothly.

Final Thoughts

Ultimately, the right seal bar comes down to what your packaging line really needs, whether that’s speed, cost savings, or a clean, professional finish. Each type of seal bar brings something different to the table, and knowing those differences helps you make smarter, more confident decisions. Our solutions are built to make the most of each sealing method, and our team is here to help you choose the one that fits your goals.

If sorting through your options feels overwhelming, you’re not alone, and you don’t have to figure it out by yourself. We take the time to understand your products, your process, and your priorities, so we can guide you to the sealing solution that truly works for you.

When you’re ready to simplify your packaging process and take the next step toward efficiency and confidence, let’s talk. We’re here to help you seal your success.