Customer Success Story: Handcraft Manufacturing

At Handcraft Manufacturing, they are America’s leading provider in high-quality children’s clothing, the company also produces a wide range of apparel and accessories for all ages. But behind the success of its popular product lines was a warehouse operation held back by fully manual packaging processes, until the team turned to Tomar Industries and BestPack to usher in a new era of automation.

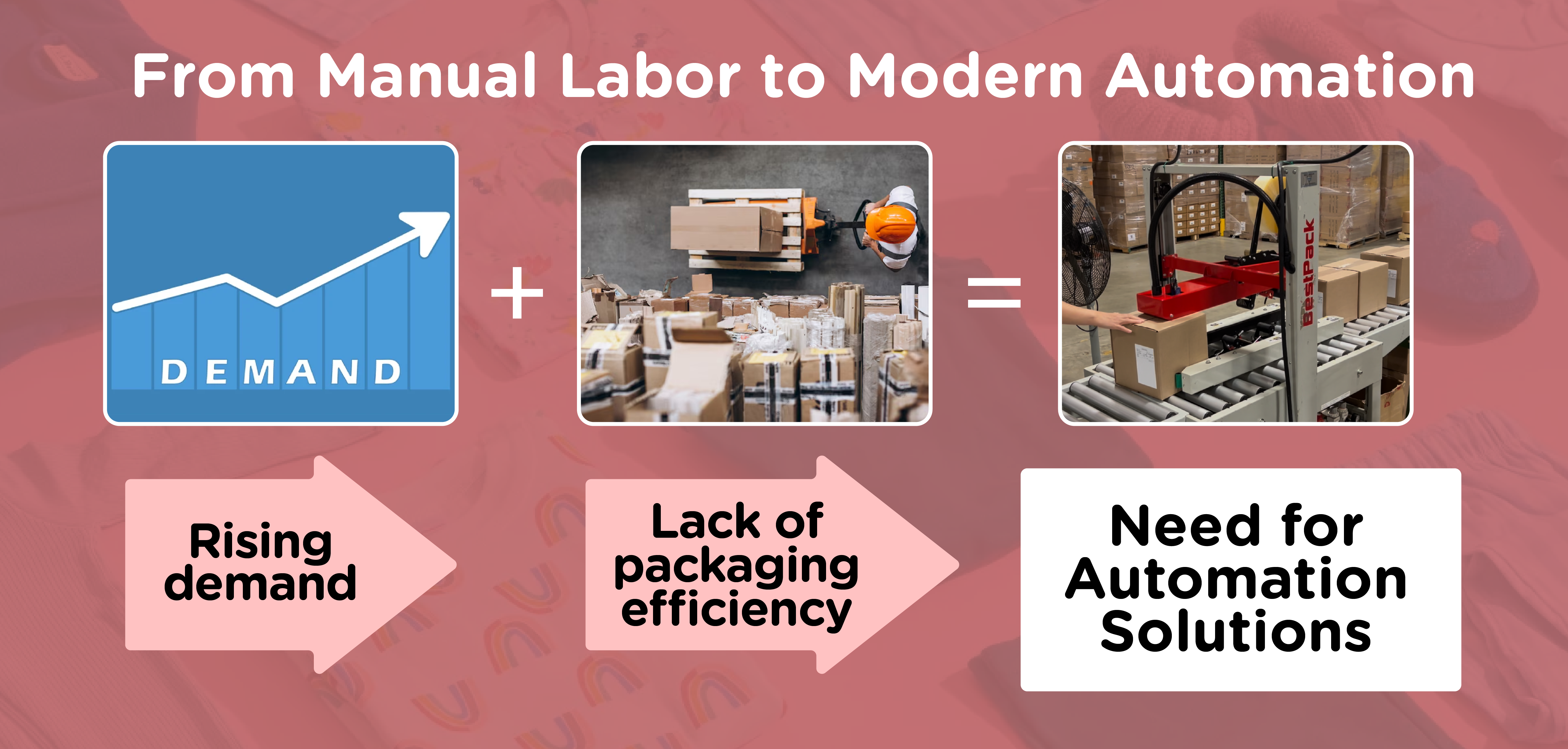

From Manual Labor to Modern Automation

Before automation, every package that left Handcraft’s facility was manually erected, packed, and sealed—a time-consuming process that demanded intensive labor and limited throughput. As order volume grew, the company knew this model wasn’t sustainable.

“We had no automation whatsoever in our facility,” said the Logistics Manager at Handcraft. “Everything had to be done manually, and as demand increased, we simply couldn’t keep up.”

Rising demand and a lack of packaging efficiency pushed Handcraft to seek out automation solutions that could scale with their needs.

Tomar Industries, a long-time packaging partner, visited Handcraft’s facility to assess its workflow and challenges. Together with BestPack, they recommended a packaging system tailored to Handcraft’s application, floor layout, and budget.

Their solution included:

“Tomar came in, evaluated our process, and offered an affordable, effective solution,” Handcraft Logistics Manager, “The affordability and hands-on support made all the difference.”

Instant Impact with Minimal Learning Curve

Handcraft’s team immediately noticed the benefits. Operators were able to learn and use BestPack equipment with ease.

“It was easy. Our team likes it, and it doesn’t take much time to get up and running,” Handcraft Logistics manager explained, “The impact was felt quickly. A pallet would take a couple hours to pack could now be done in less than 30 minutes by just one operator.”

Reliable Results, Real-Time Support

Handcraft experienced minimal downtime. Occasional minor snags were addressed swiftly, thanks to Tomar’s continued support and check-ins.

“What I like about Tomar is they don’t just disappear after installation—they stop by and check up on us to make sure everything’s working right.”

BestPack’s machinery proved to be reliable, low-maintenance, and highly intuitive for the team to operate, delivering clean, consistent seals every time.

“The equipment just works. And it’s easy to maintain.”

Building for the Future

For Handcraft, this is only the beginning of its automation journey. The success of the initial implementation has opened the door to broader automation goals.

“This is just the start,” said Handcraft Manager. “We’ll continue using BestPack equipment with Tomar’s support. When the time is right, we’ll look into adding even more automation.”

Final Thoughts

What started as a manual, labor-intensive operation is now a streamlined, scalable packaging line—thanks to the combined expertise and service of Tomar Industries and BestPack.

“Our operators actually enjoy using BestPack’s equipment,” Handcraft Manager concluded. “That makes all the difference.”