Single Jaw vs. Dual Jaw Flow Wrappers: What’s the Difference and Which One Do You Need?

Understanding Your Flow Wrapper Options

When it comes to getting single wrapped products out the door fast, a flow wrapper helps you move quickly without sacrificing quality. Whether you’re packaging snacks, medical supplies, or items that need to be individually wrapped, choosing the right flow wrapper setup is key to keeping your production smooth and consistent. One of the most important choices you’ll make? Deciding between a single jaw or dual jaw sealing system.

If you’re new to this world, don’t worry, we’re breaking it all down in simple terms so you can make the best decision for your operation.

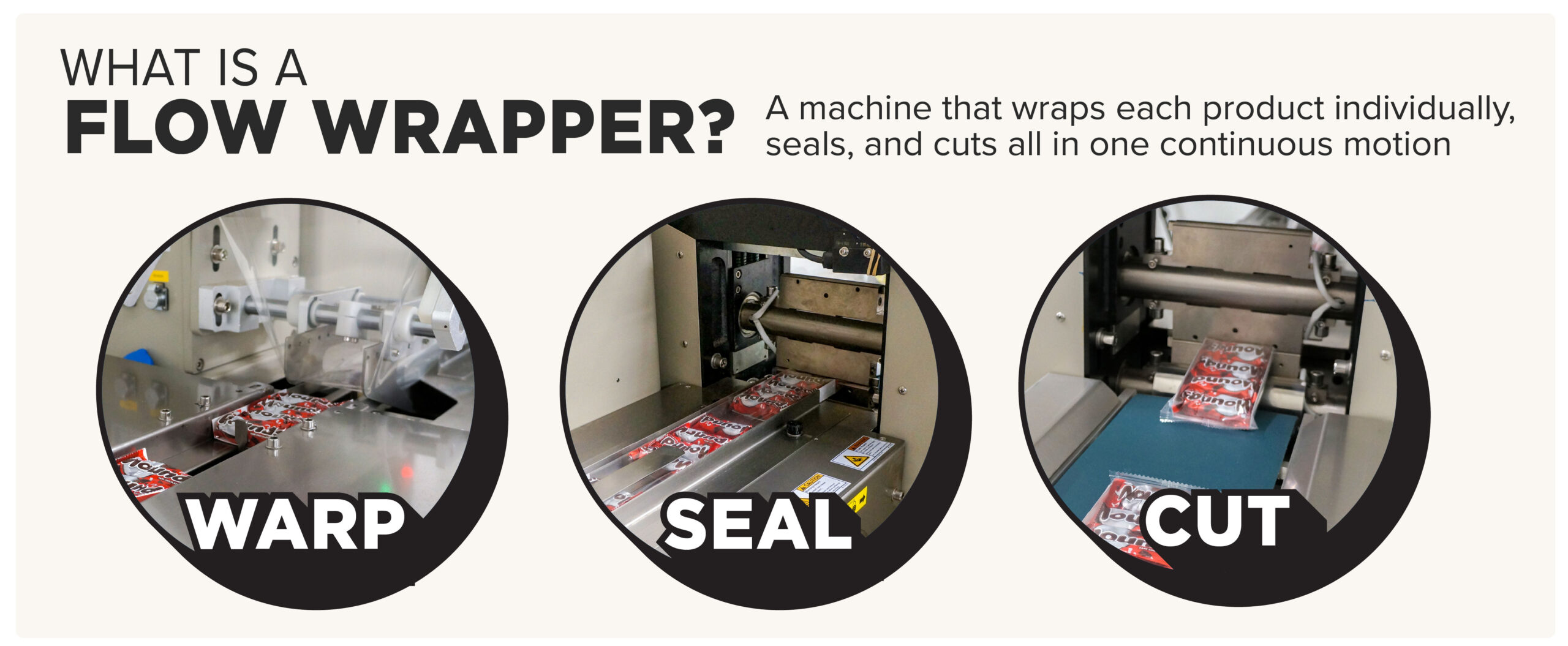

What Is a Flow Wrapper?

A flow wrapper is a machine that wraps each product in one layer of plastic, then seals and cuts the film around it, all in one continuous motion. Each item gets its own neatly sealed package, giving it a clean, professional look. It’s a fast and efficient way to keep your products protected and ready to ship.

At the heart of the machine is something called a jaw, it’s what seals and cuts the film. And when it comes to jaws, you’ve got two options: single or dual.

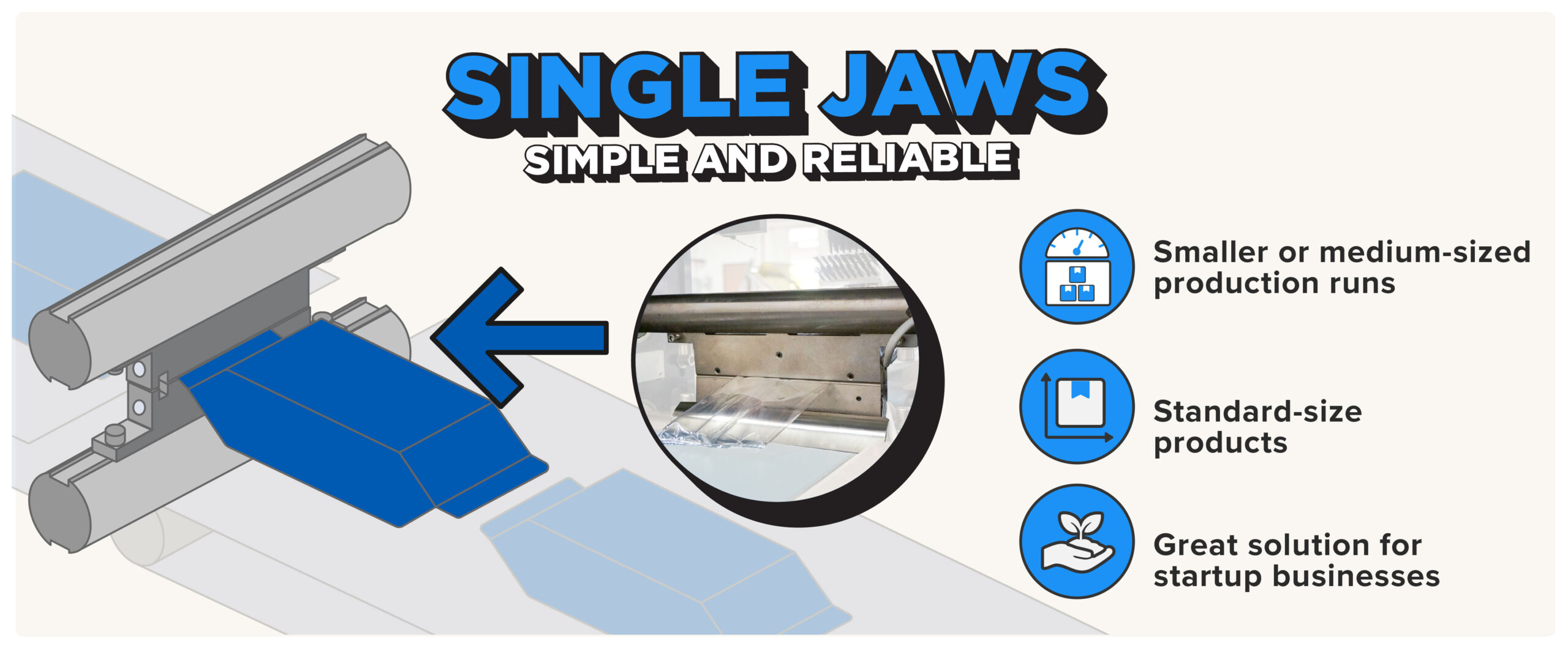

Single Jaw – Simple and Reliable

A single jaw flow wrapper uses one set of sealing jaws to cut and seal the film at a time. It’s reliable, easy to operate, and great for operations that don’t require lightning-fast output.

Best for:

The single jaw option is more budget-friendly and involves fewer moving parts, which means it’s easier to maintain and troubleshoot.

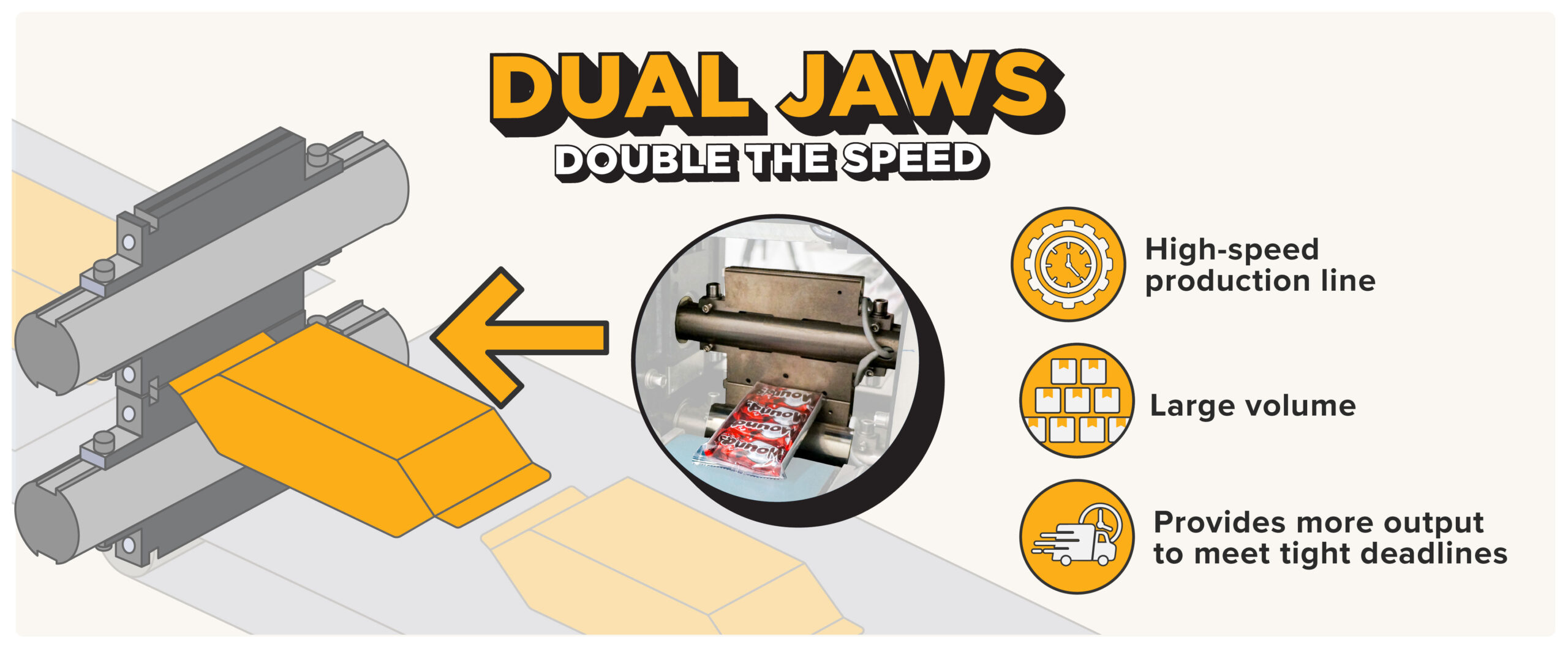

Dual Jaw – Double the Speed

On the other hand, a dual jaw flow wrapper uses two sets of jaws that work alternately. While one jaw seals, the other resets and gets ready to seal the next pack. This setup allows the machine to run much faster, increasing your output without sacrificing seal quality.

Best for:

Dual jaws offer increased efficiency but may require more upkeep and a higher initial investment.

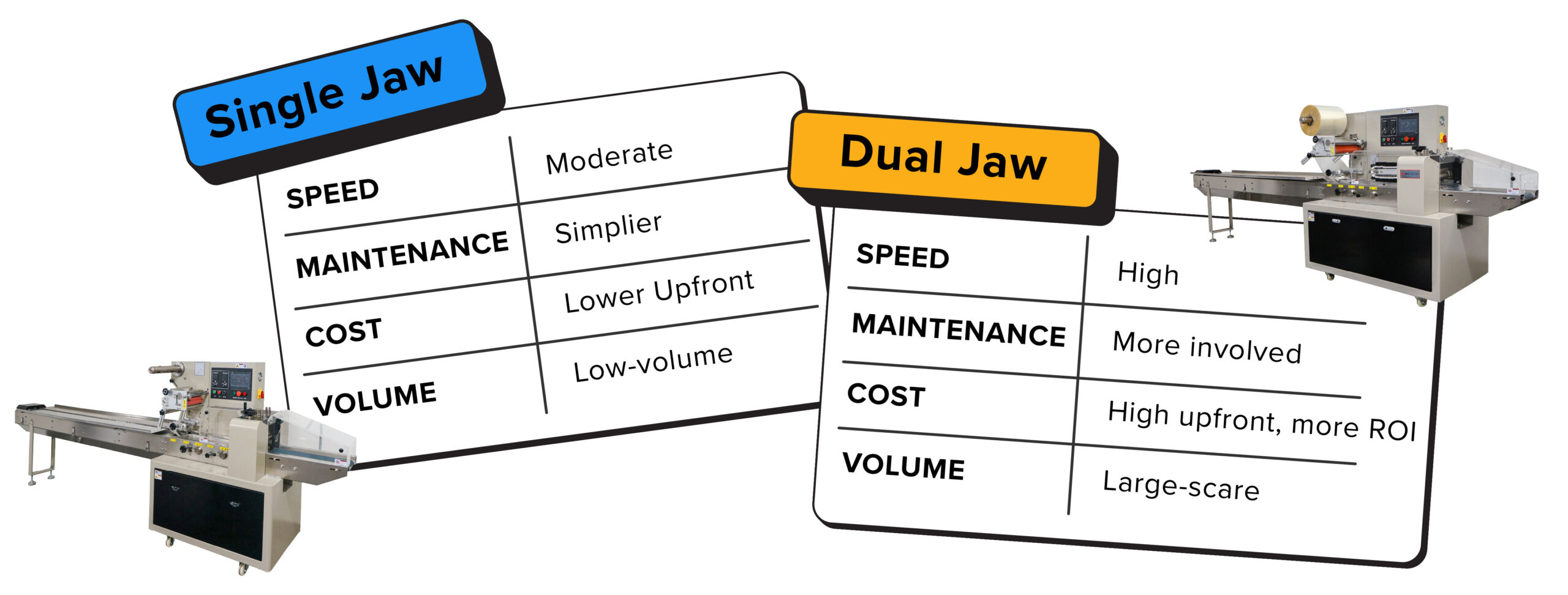

Key Differences at a Glance

Choosing What’s Right for You

Let your production needs lead the way.

When choosing between a single or dual jaw flow wrapper, ask yourself:

If you’re just starting out or have consistent but slower throughput, a single jaw will serve you well. But if you’re scaling quickly and need to increase output, a dual jaw system can help you hit your goals.

Find Your Perfect Fit with Confidence

Choosing between a single jaw and dual jaw flow wrapper all comes down to what your packaging line really needs (speed, volume, budget, and more). There’s no one-size-fits-all answer, but knowing the difference gives you a real advantage.

Still not sure which setup is right for you? You’re not alone, and you don’t have to figure it out by yourself. With the right support and guidance, you’ll find a setup that meets your exact needs, no matter your daily output.

Let’s talk about how the right setup can keep your line flowing and your business growing.